ENGINEERING

Comprehensive, In-House Expertise & Excellence

At Ruiter Innovations, engineering isn’t just a department—it’s the foundation of everything we do. With all four branches of engineering under one roof, our team has the capability to design, develop, and deliver complete process solutions from concept to finished product.

Our partnership with MW Control Systems further enhances our ability to deliver automation and control technology that’s precise, reliable, and built for the future. Together, we offer start-to-finish system design that meets the highest standards of performance, safety, and scalability.

Four Branches. One Seamless Solution.

1

Process Engineering

Our process engineers transform ideas into working systems. From a ratio or recipe, we create a complete, operational process—mapping every stage from intake to milling, mixing, and loadout (or in brewing applications, from milling to mashing, fermenting, and packaging).

We analyze your production goals and develop custom process flow designs that optimize throughput, accuracy, and efficiency across your entire operation, whether you’re producing livestock feed, wild birdseed, flour blends, spice mixes, or ready-to-drink or fermented beverages.

2

Mechanical Engineering

Within each process, our mechanical engineers design the physical framework that makes it work. We select, design, and integrate equipment according to your process requirements, ensuring that every component, connection, and conveyor aligns with your production flow.

From conveying systems and mixers to loadout structures and packaging lines, we bring the mechanics of your process to life with precision, durability, and performance-driven design.

3

Electrical Engineering

Our electrical engineering team delivers the power and protection behind every system.

We design and build Motor Control Centers (MCCs), wiring schematics, and panel layouts that form the backbone of your operation.

Every connection is built for reliability, safety, and ease of maintenance, ensuring your plant runs efficiently from startup through continuous production.

4

Automation Engineering

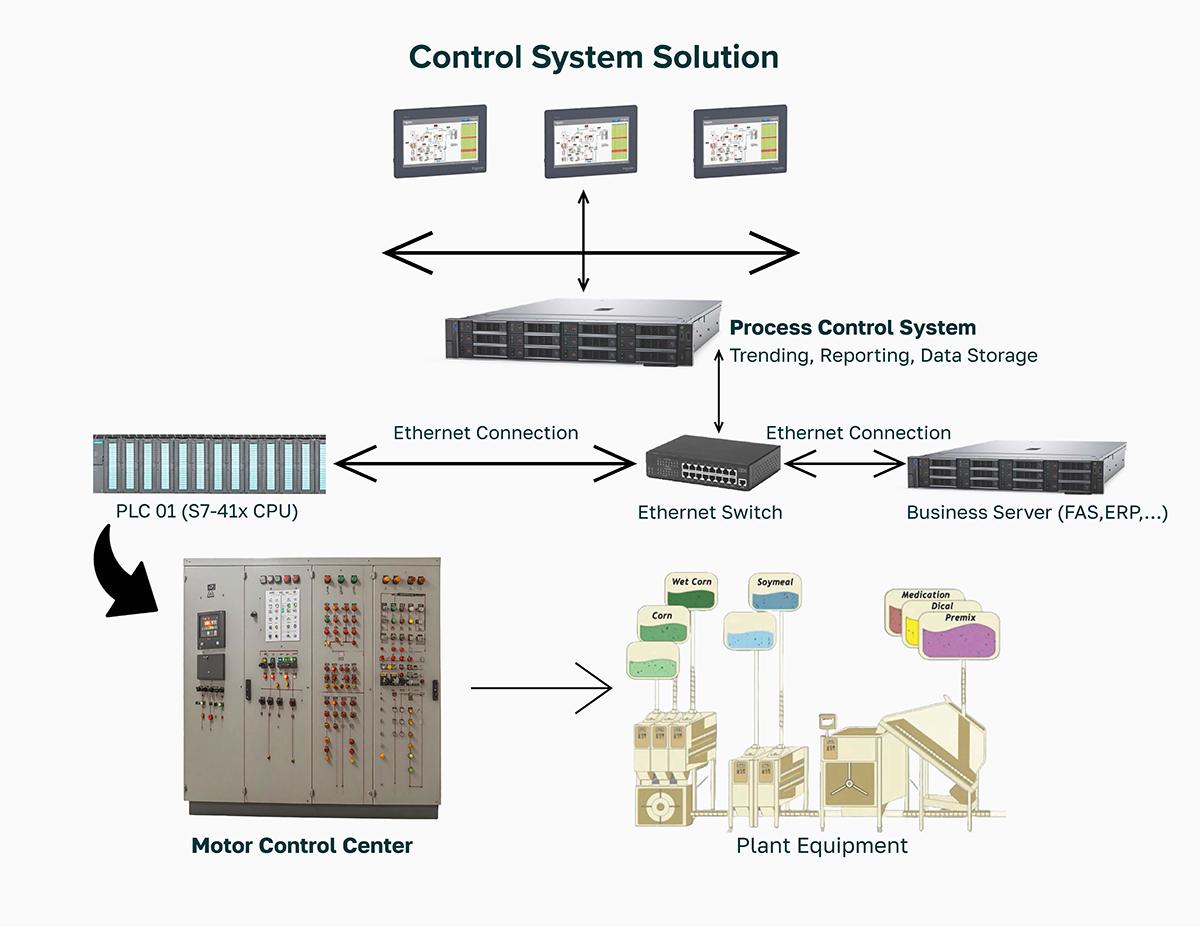

Automation is where engineering meets intelligence—and where Ruiter Innovations excels. In collaboration with MW Control Systems, our automation engineers develop customized, adaptable software that transforms mechanical processes into smart, self-optimizing systems.

Our automation team programs and integrates PLC, HMI, and SCADA solutions that give operators full control and real-time visibility of production. From batching and reporting to recipe handling and diagnostics, our front-end control interface is intuitive, user-focused, and tailored to your operation.

Integrated Engineering • All In-House

We don’t just design equipment—we engineer complete solutions that are built to perform, built to last, and built entirely by Ruiter Innovations.

Because every engineering branch operates on-site at Ruiter Innovations, we can deliver:

Total system integration,

with mechanical, electrical, and automation engineering working in harmony.

Custom-built designs

that are tailored precisely to your process and production scale.

Efficient project delivery

—no third-party delays, no communication gaps.

Superior quality control,

with every system designed, tested, and supported in-house.

Built for Countless Industries

Whether your operation focuses on milling and mixing or mashing and fermenting, our multidisciplinary team has the experience and technical depth to engineer a solution that works from day one and keeps working for decades.

Ready to Get Started?

Ruiter Innovations is engineering the future of process automation.