CONTROL SYSTEMS

Next-Generation, Full-Package Control Solutions That Are Customizable & Ready-to-Go

Ruiter Innovations has partnered with MW Control Systems to reshape material handling and process automation. From our engineering base in Pella, Iowa, we design and build precision, next-generation, full-package control systems that power entire operations—from front-end HMI/SCADA to Motor Control Centers (MCC) and plant Process Control Systems (PCS).

Built for Your Process • Custom, Complete, & Affordable

Our full-package control solutions are customizable and individually programmed to your exact application parameters. Because we design and build everything in-house, you get a fully integrated system at a competitive price—no layered add-ons, no unnecessary middlemen.

What that means for you:

- A turnkey system that’s delivered ready to run. Batching, reporting, recipe handling, and more are included out of the box.

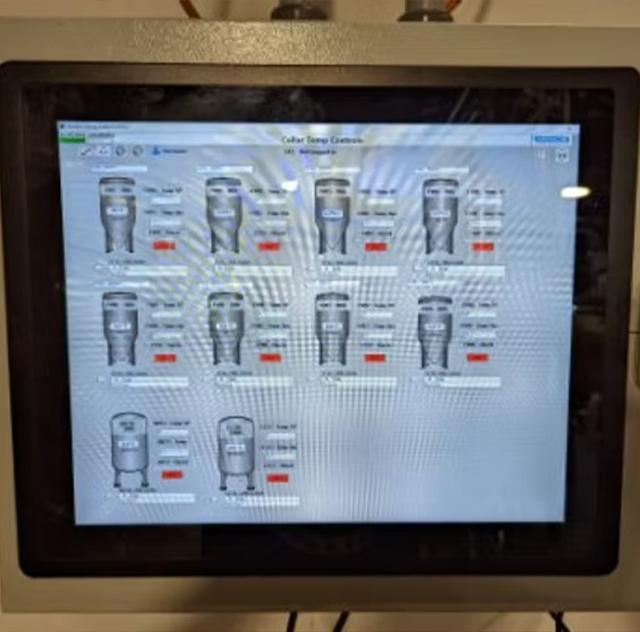

- Custom front-end HMI/SCADA screens that are clear, intuitive, and tailored to operator workflows.

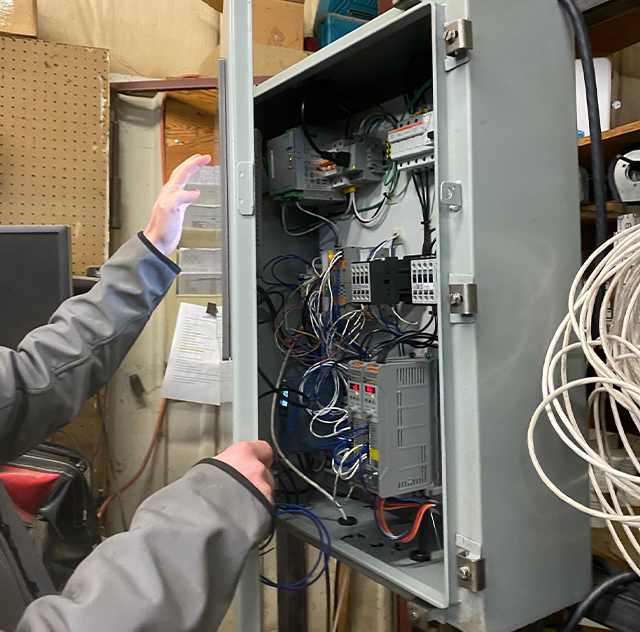

- Motor Control Centers (MCC) with Programable Logic Controller (PLC) and Process Control System (PCS) integration. These act as the “brain of the operation” and are engineered for reliability and simple maintenance.

- Comprehensive documentation and functional descriptions, so your team can operate and maintain systems confidently.

Why This Partnership Matters

Ruiter Innovations brings a long reputation for reliability, durability, and practical engineering. MW Control Systems brings cutting-edge automation software and modern control architecture. Together we deliver solutions that are:

Precision-engineered

for performance and repeatability.

Modular and scalable

to grow with your operation.

Cost-effective

because the design, programming, and fabrication happen under one roof.

User-friendly

with operator-focused HMI and clear SCADA visualization.

Core Capabilities & Included Functionality

Our full-package systems are designed to be truly comprehensive. Standard features include:

- Batch control and sequencing

- Extensive recipe management and “endless” recipe handling

- Automatic reporting and data logging

- Remote monitoring and diagnostics-ready architecture

- Integrated MCCs with protection, starters, and VFDs where required

- PCS/PLC integration for plantwide coordination

- User documentation and startup support

Because these capabilities are built into the base system, you avoid paying incremental fees for commonly required modules.

Engineering & Support

We understand the realities of production: downtime costs money, complexity creates training burdens, and visibility saves time.

Our solutions focus on:

- Operational simplicity, with clear front-end displays (HMI/SCADA) that reduce operator error.

- Reliability through robust MCCs and control hardware that’s designed for continuous operations.

- Scalability through modular platforms that expand without needing a full system redesign.

- Transparency with built-in reporting and data capture for traceability and optimization.

Ready to Get Started?

Contact us to discuss your process, request a capability brief, or schedule an on-site evaluation. Let’s build a partnership that powers performance—for life.